mobile padel court factory

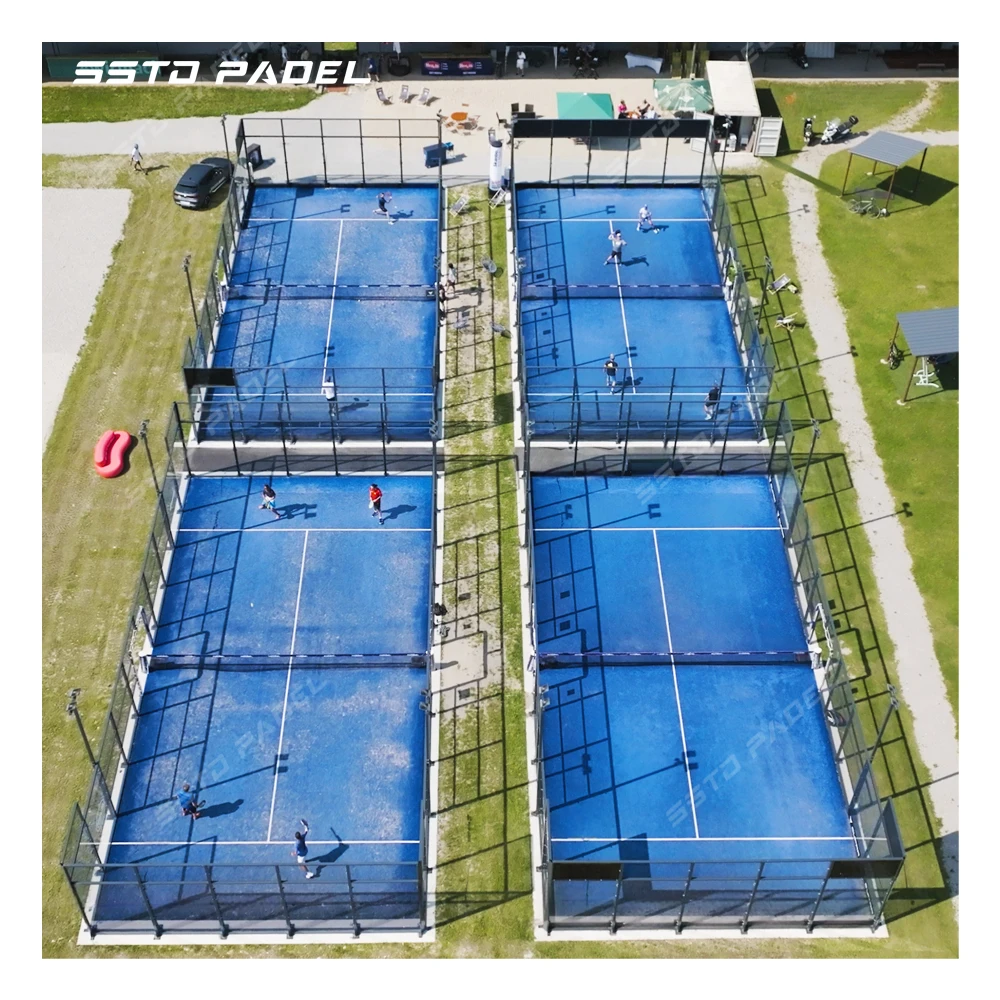

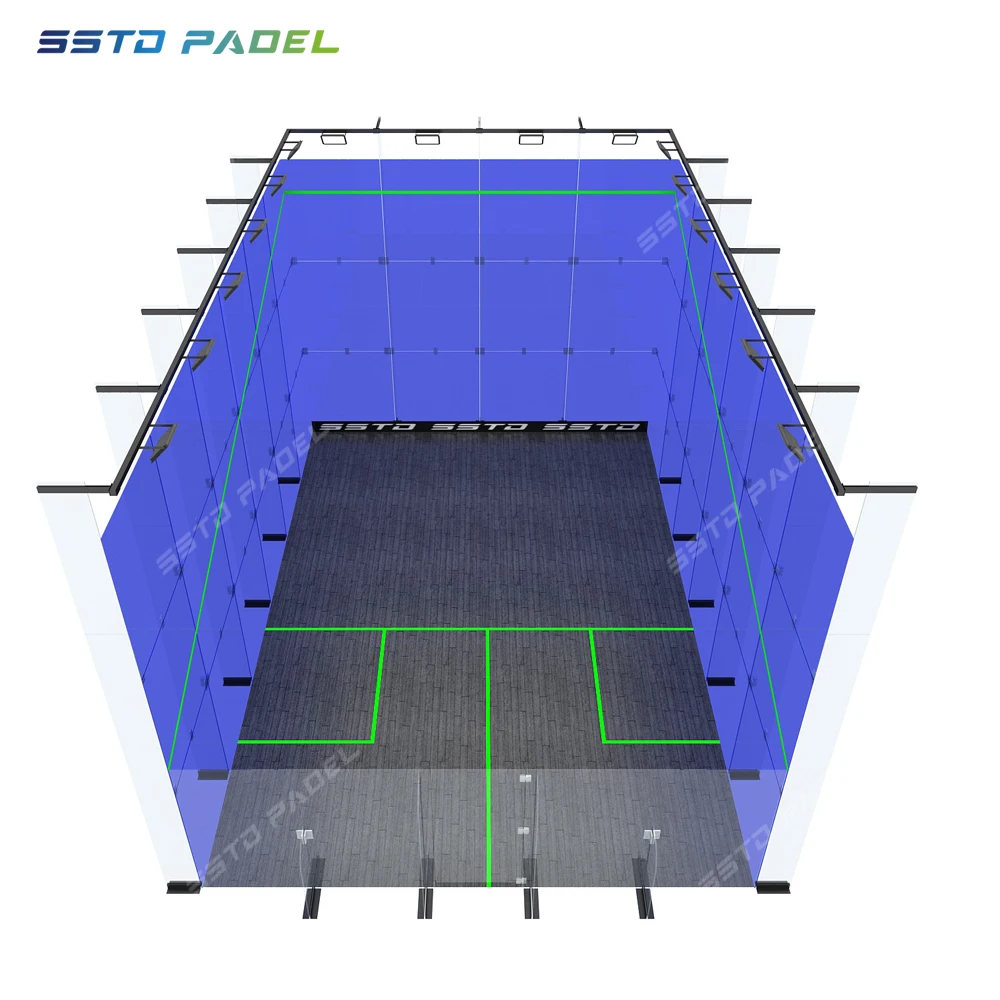

A mobile padel court factory represents a cutting-edge manufacturing facility designed to produce portable and easily assemblable padel courts. These specialized facilities combine advanced engineering with efficient production processes to create courts that meet international standards while maintaining mobility. The factory utilizes state-of-the-art manufacturing technology, including precision metal fabrication, automated welding systems, and quality control measures to ensure each court component meets strict specifications. The production line incorporates modern CNC machinery for accurate cutting and shaping of materials, alongside advanced coating systems for weather resistance. The facility's design allows for simultaneous production of multiple court components, from the structural framework to the tempered glass panels and artificial turf surfaces. Quality testing stations are integrated throughout the production process, examining structural integrity, material durability, and assembly mechanisms. The factory's modular manufacturing approach enables customization options while maintaining consistent quality standards. Special attention is given to the development of innovative connection systems that facilitate quick assembly and disassembly without compromising structural stability. The facility also includes research and development capabilities for continuous improvement of court designs and materials, ensuring products meet evolving market demands and safety requirements.