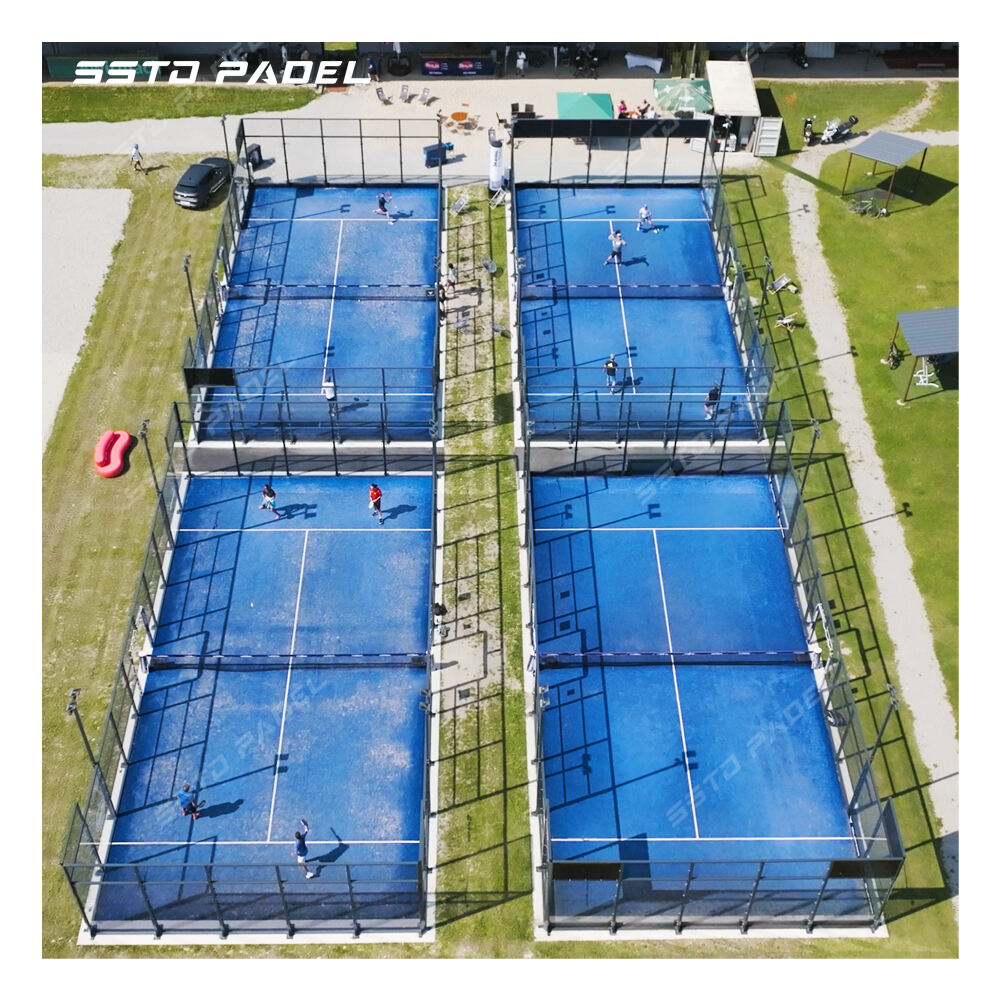

single padel tennis factory

The single padel tennis factory represents a state-of-the-art manufacturing facility dedicated to producing high-quality padel tennis courts and equipment. Operating with advanced automation systems and precision engineering, this facility combines innovative technology with expert craftsmanship to deliver superior products. The factory utilizes cutting-edge manufacturing processes, including computer-controlled cutting machines, automated welding systems, and quality control stations equipped with advanced testing equipment. A significant feature is its integrated production line that handles everything from raw material processing to final assembly. The facility incorporates sustainable manufacturing practices, utilizing energy-efficient machinery and implementing waste reduction protocols. With a production capacity of up to 100 courts per month, the factory maintains strict quality control measures throughout each manufacturing phase. The facility houses specialized areas for glass tempering, frame construction, and surface treatment, ensuring each component meets international standards. Advanced logistics systems manage inventory and distribution, while dedicated research and development teams continuously work on product improvements and innovations. The factory's modular design allows for rapid scaling of production based on demand, while maintaining consistent quality standards.