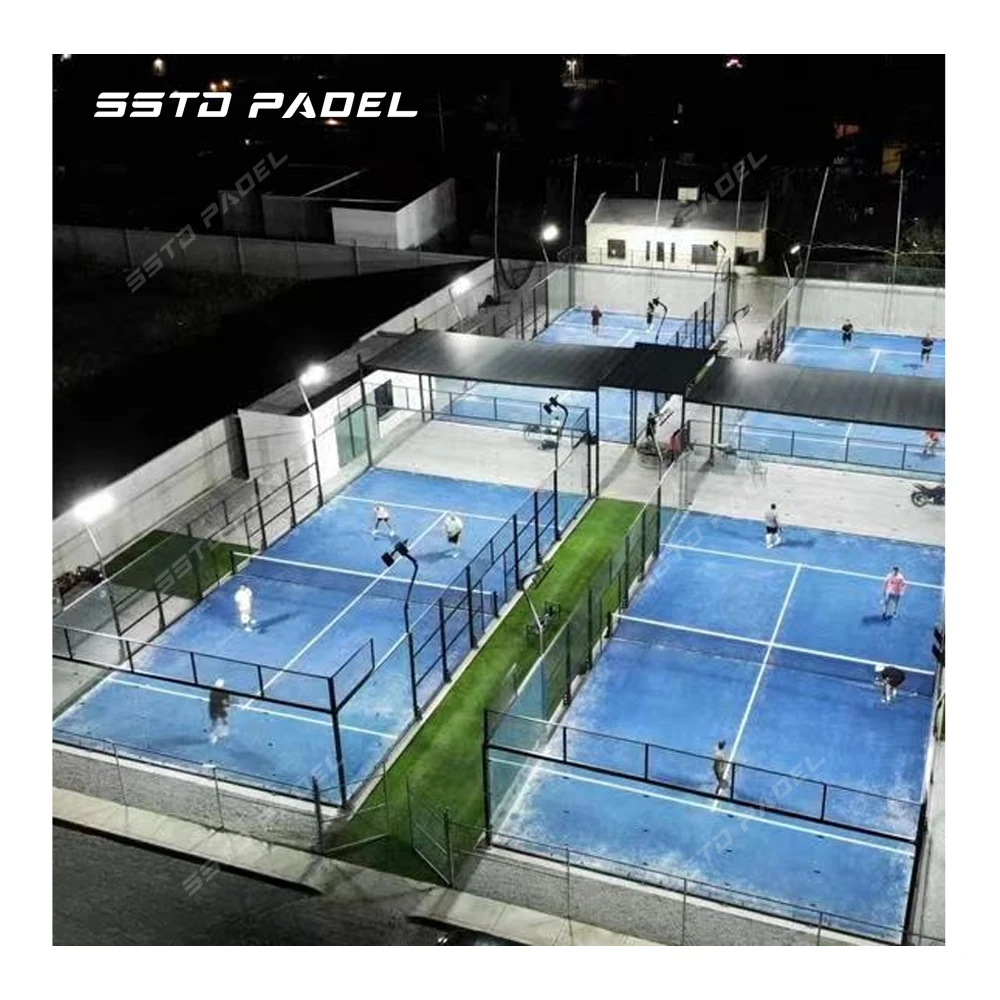

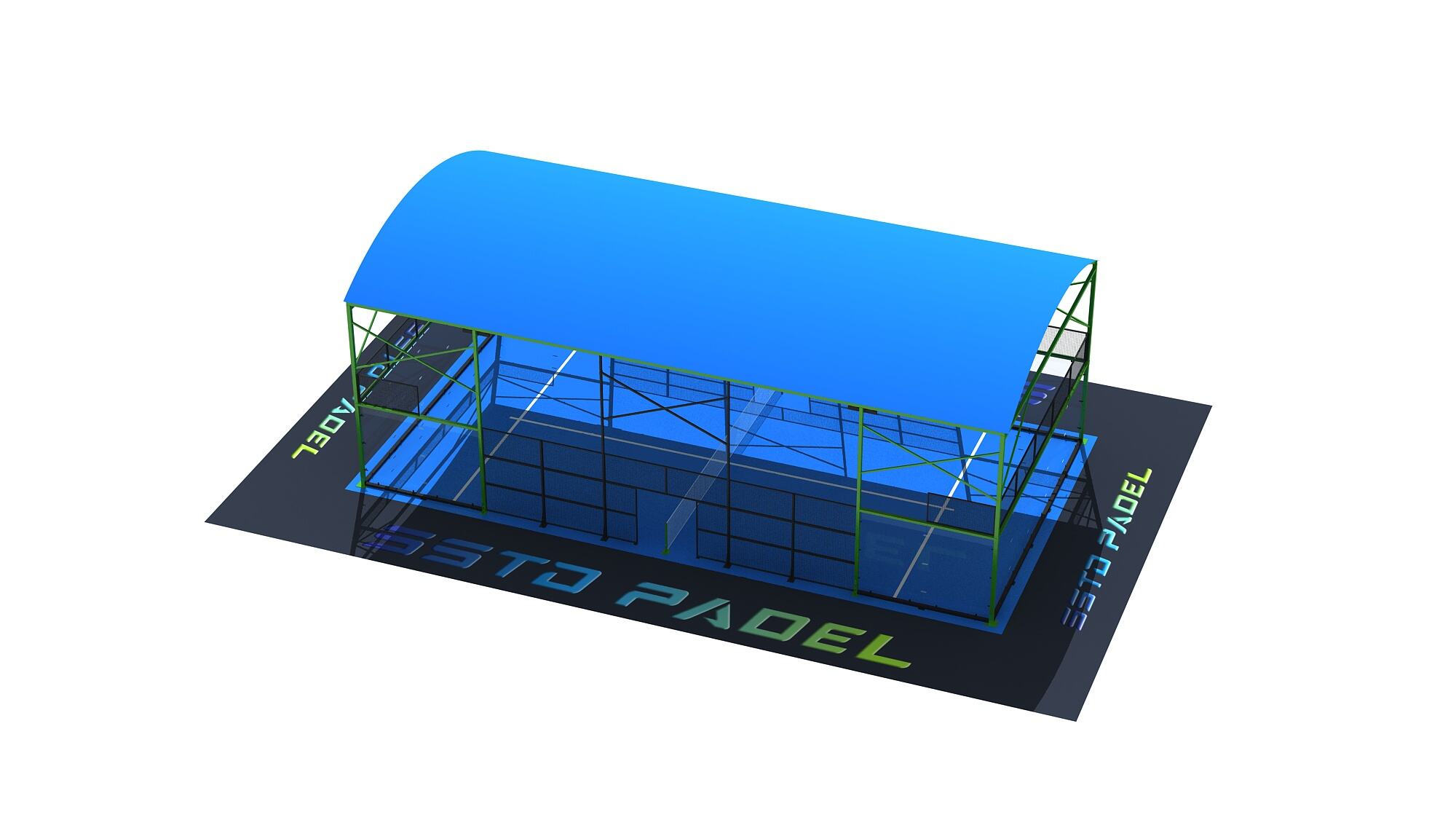

outdoor padel court factory

An outdoor padel court factory represents a state-of-the-art manufacturing facility dedicated to producing high-quality padel courts designed for outdoor installation. These specialized facilities combine modern engineering with precision manufacturing to create durable, weather-resistant courts that meet international padel federation standards. The factory employs advanced production techniques, including automated welding systems, powder coating technology, and quality control measures to ensure each court component meets rigorous specifications. The manufacturing process encompasses the production of structural steel frames, tempered glass panels, artificial turf surfaces, and LED lighting systems. The facility's production line is optimized for efficiency, capable of manufacturing multiple court components simultaneously while maintaining strict quality standards. Advanced computer-aided design (CAD) systems enable precise customization of court dimensions and features according to client specifications. The factory also incorporates sustainable manufacturing practices, utilizing energy-efficient equipment and recyclable materials where possible. Quality testing facilities within the factory ensure all components meet safety and durability requirements before shipping.