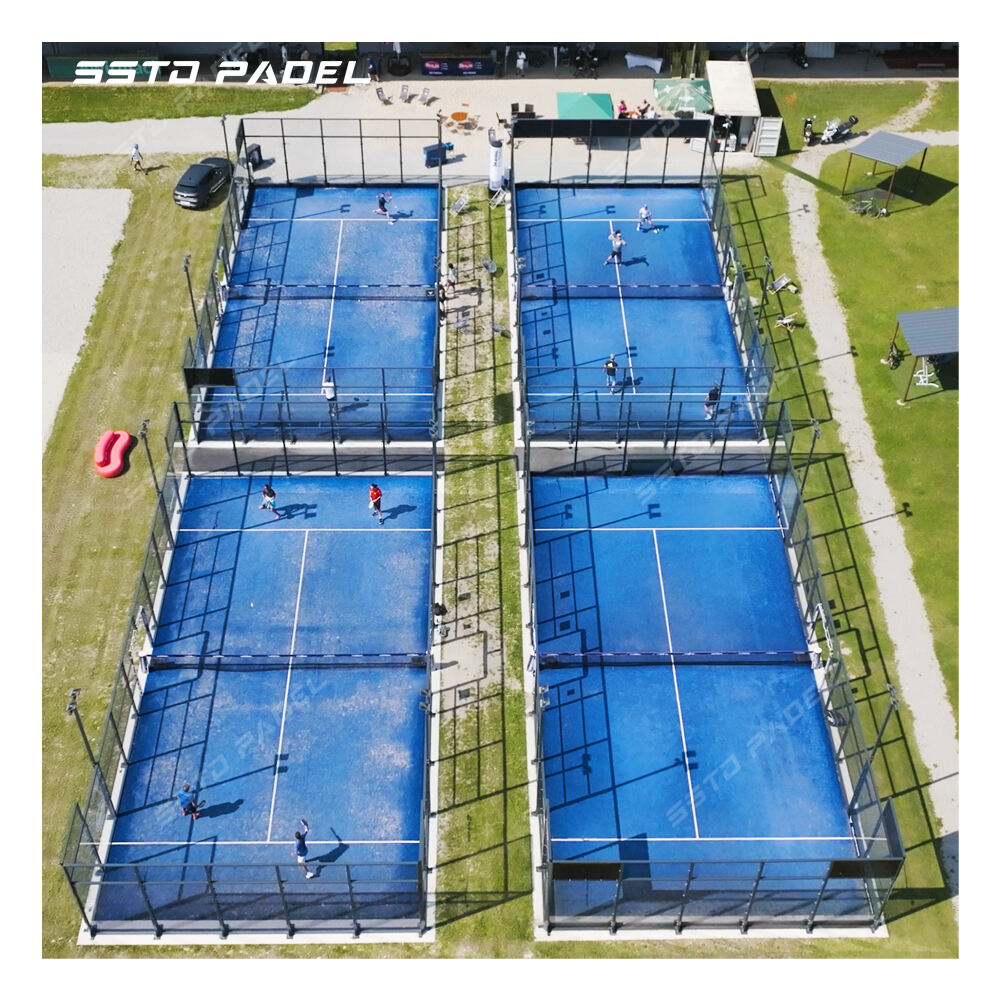

paddle ball court factory

A paddle ball court factory represents a state-of-the-art manufacturing facility dedicated to producing high-quality courts for paddle tennis and similar racquet sports. The facility incorporates advanced construction techniques and modern materials science to create durable, professional-grade playing surfaces. These factories utilize precision engineering equipment to ensure exact measurements and specifications for court dimensions, incorporating specialized drainage systems and surface treatments for optimal player performance. The manufacturing process includes the production of court walls, typically made from tempered glass and metallic structures, along with specialized synthetic turf or concrete playing surfaces. Quality control systems monitor every aspect of production, from the initial material selection to the final court assembly. The factory's capabilities extend to customization options, allowing for adjustments in court size, surface type, and enclosure specifications to meet various client requirements. Modern paddle ball court factories also emphasize sustainability in their operations, implementing energy-efficient manufacturing processes and utilizing eco-friendly materials where possible. The facility includes dedicated areas for research and development, where new technologies and materials are tested to enhance court performance and durability. Additionally, these factories maintain comprehensive testing facilities to ensure all products meet international sports facility standards and safety regulations.