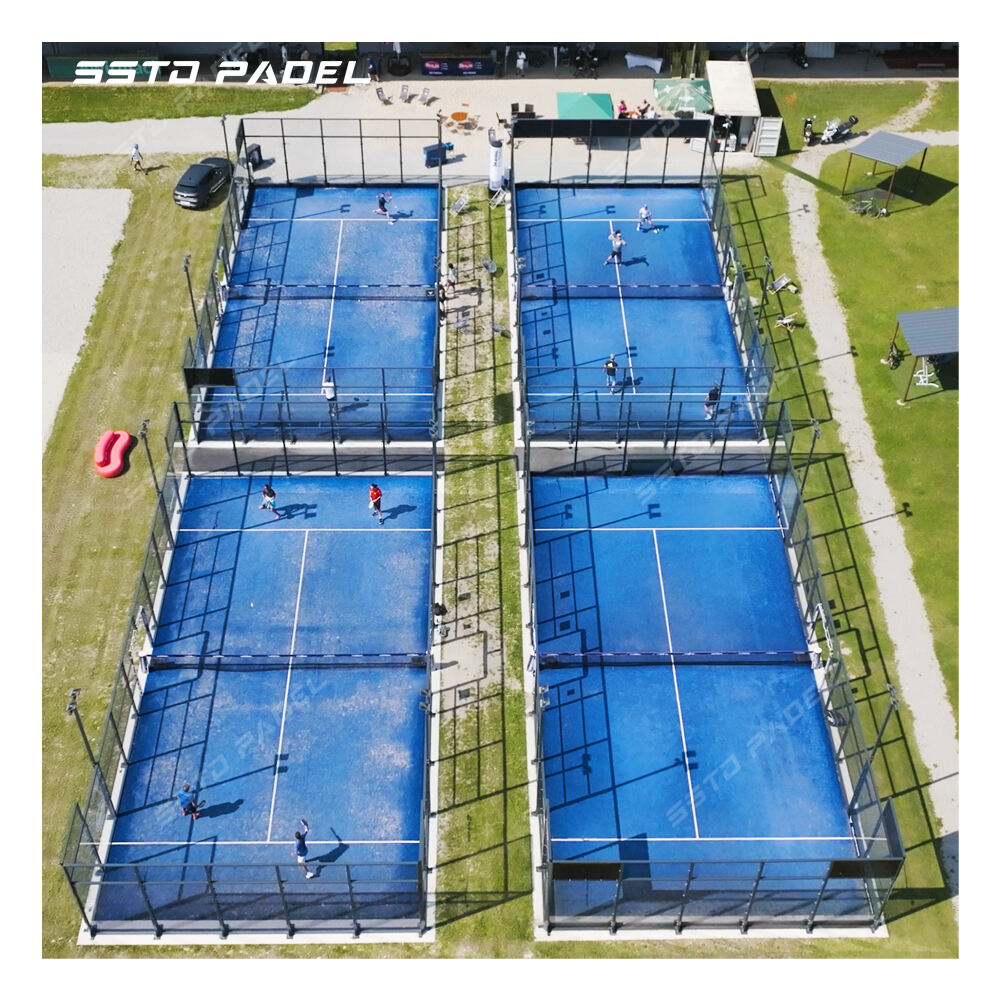

tennis paddle court factory

A tennis paddle court factory represents a state-of-the-art manufacturing facility dedicated to producing high-quality tennis and paddle court surfaces and equipment. The facility combines advanced manufacturing technologies with precision engineering to create durable, professional-grade court surfaces that meet international standards. The factory utilizes automated production lines equipped with cutting-edge machinery for surface preparation, coating application, and quality control testing. These facilities incorporate environmentally conscious manufacturing processes, including water-based coating systems and recycled materials where possible. The production center features dedicated areas for different manufacturing stages, from raw material processing to final assembly, ensuring efficient workflow and consistent quality. Modern climate control systems maintain optimal conditions for material curing and storage, while sophisticated quality control stations employ laser-guided measurement tools and impact testing equipment to verify product specifications. The factory also houses research and development facilities where new surface technologies and court designs are tested and refined. With computer-aided design capabilities and automated cutting systems, the facility can produce customized court components to meet specific client requirements and adapt to various installation environments.