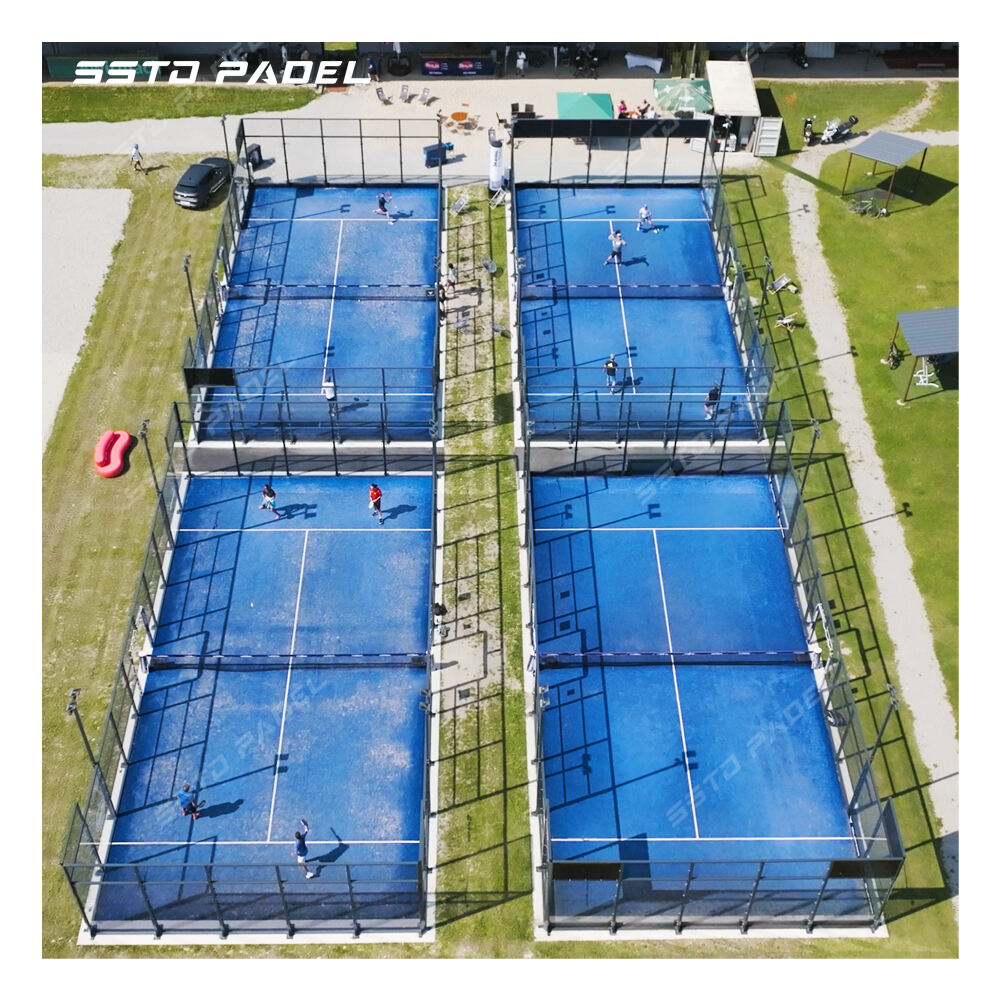

single padel tennis manufacturer

A single padel tennis manufacturer stands as a specialized entity dedicated to producing high-quality padel tennis courts and equipment through innovative manufacturing processes. These manufacturers employ advanced engineering techniques and premium materials to create durable, professional-grade padel courts that meet international standards. The manufacturing process incorporates cutting-edge technology for precise structural design, weather-resistant materials, and optimal playing surface characteristics. These facilities typically feature automated production lines, quality control systems, and specialized testing equipment to ensure consistent product quality. The manufacturer's scope extends beyond mere court construction to include integrated lighting systems, professional-grade glass panels, artificial turf installation, and comprehensive drainage solutions. They utilize state-of-the-art computer-aided design (CAD) software for accurate court dimensioning and structural calculations, ensuring each court meets specific regional requirements and safety standards. The manufacturer also provides customization options, allowing clients to select various court features, including turf colors, lighting configurations, and aesthetic elements to match specific venue requirements.