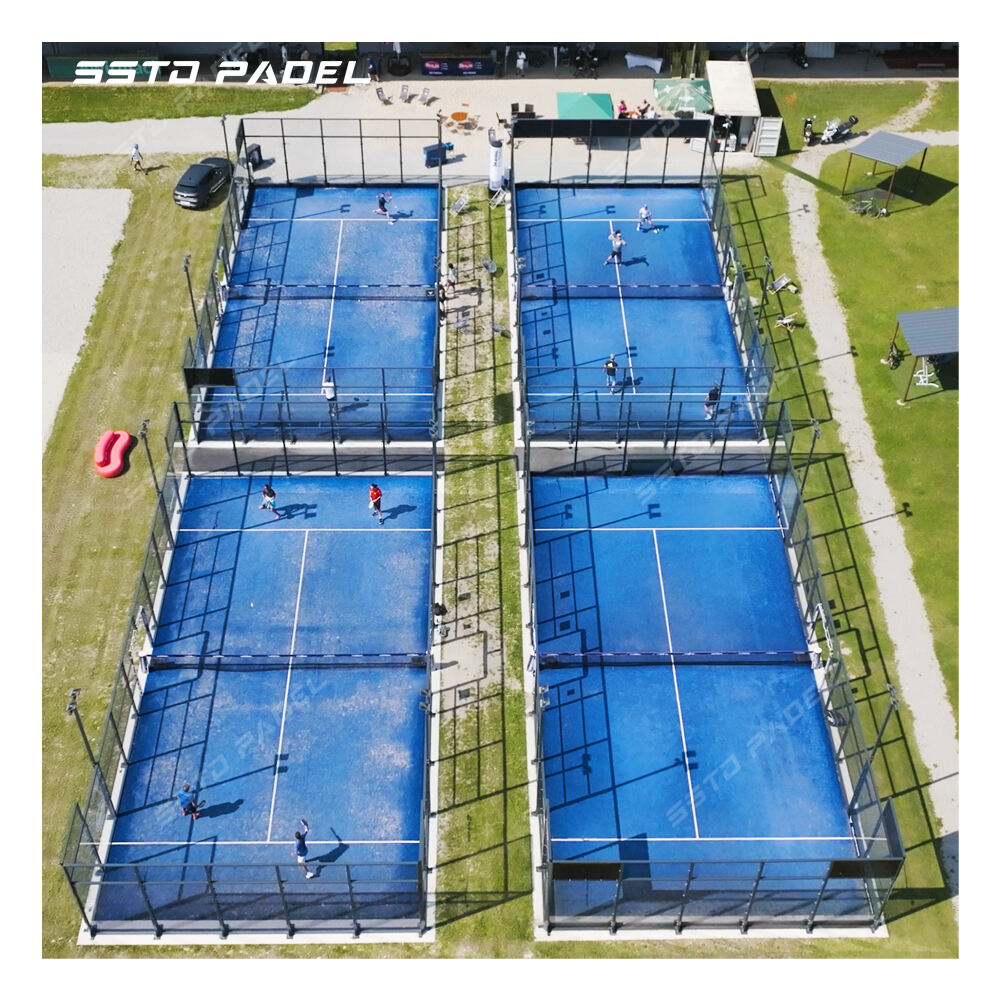

paddle court roof factory

The paddle court roof factory represents a state-of-the-art manufacturing facility dedicated to producing high-quality roofing solutions for paddle tennis courts. This specialized facility combines advanced engineering principles with innovative manufacturing processes to create durable, weather-resistant roof systems that protect paddle courts from various environmental elements. The factory utilizes cutting-edge automation technology and precision equipment to ensure consistent quality in every roof component produced. The manufacturing process encompasses everything from initial material processing to final assembly, with rigorous quality control measures implemented at each stage. The facility's production line is equipped with modern CNC machinery, automated welding systems, and advanced coating applications that ensure each roof component meets strict industry standards. The factory's capabilities extend to customizing roof designs according to specific court dimensions and local weather requirements, offering solutions that range from standard covered structures to fully enclosed systems with integrated lighting and ventilation options. With a focus on sustainability, the facility incorporates eco-friendly materials and energy-efficient manufacturing processes, while maintaining optimal production efficiency and minimal waste generation. The factory's output serves both commercial and private paddle court installations, providing comprehensive roofing solutions that enhance the playing experience and extend the usability of paddle courts throughout the year.