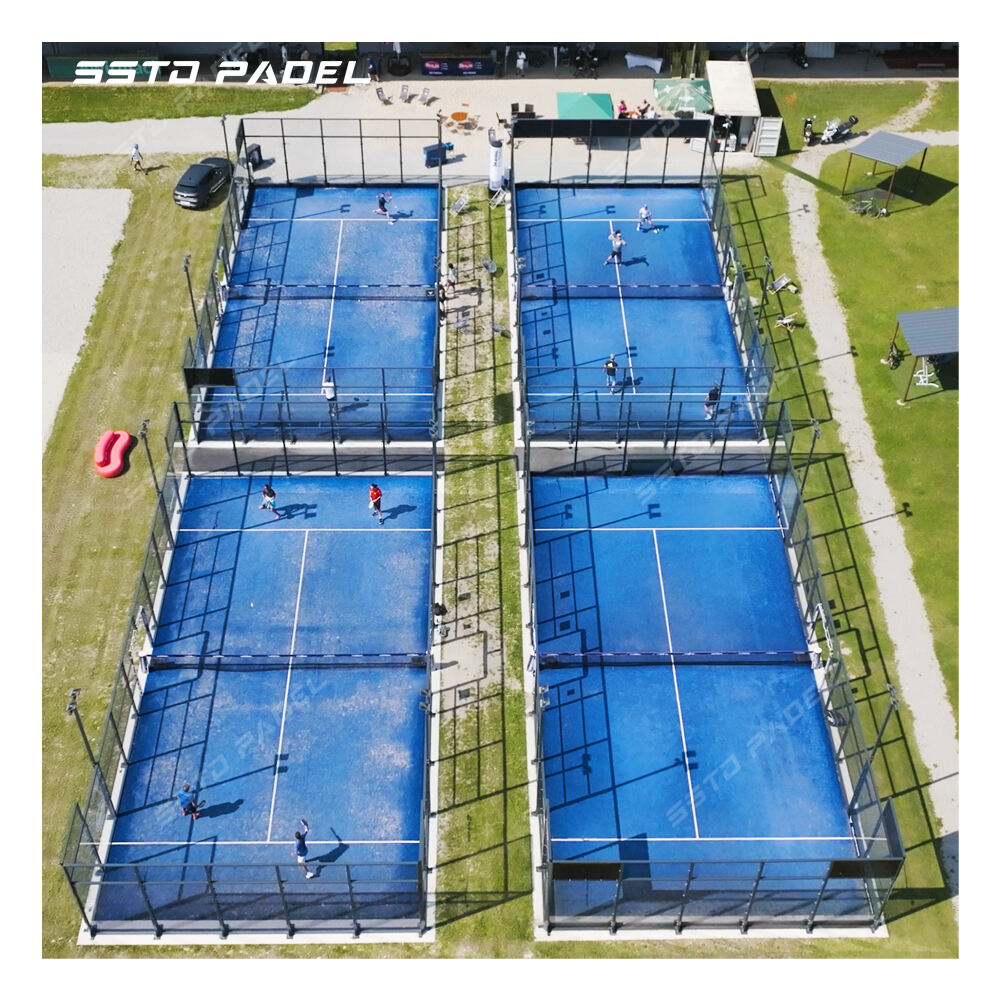

padel ground factory

A padel ground factory represents a cutting-edge manufacturing facility dedicated to producing high-quality padel court surfaces and components. These specialized facilities integrate advanced manufacturing processes, quality control systems, and innovative materials to create professional-grade padel courts. The factory utilizes state-of-the-art machinery and automated production lines to ensure precise dimensions and consistent quality in every court component. From the artificial turf installation to the tempered glass panels and structural framework, each element undergoes rigorous testing and quality assurance protocols. The facility employs advanced surface treatment technologies to enhance durability and playing characteristics, while specialized coating systems ensure weather resistance and optimal ball bounce. Modern padel ground factories also incorporate sustainable practices, including energy-efficient manufacturing processes and environmentally friendly materials. The production line typically features automated cutting systems, precision welding equipment, and specialized tools for glass panel processing. Quality control stations throughout the manufacturing process employ digital measurement tools and testing equipment to verify compliance with international padel court standards. These factories often maintain research and development departments focused on improving court design, materials, and installation methods to enhance player experience and product longevity.