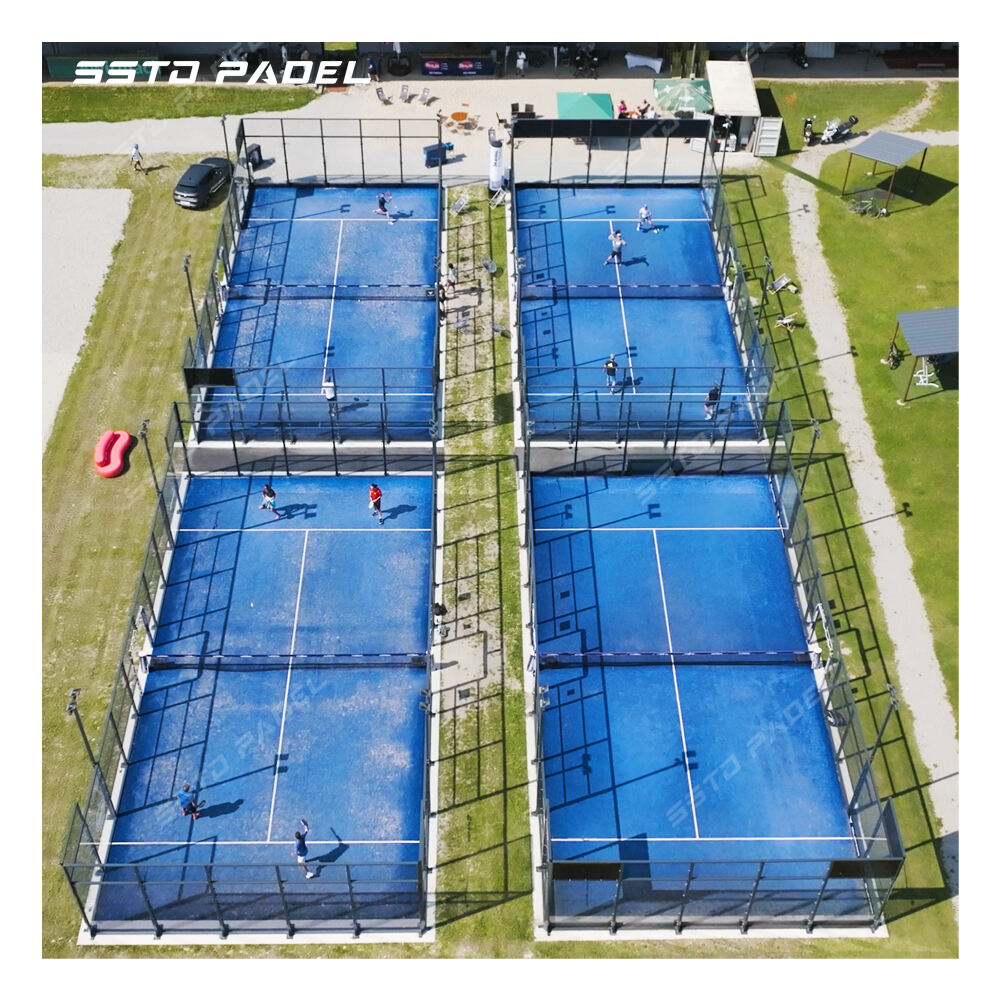

padel double court factory

The padel double court factory represents a state-of-the-art manufacturing facility dedicated to producing premium quality padel tennis courts. This specialized facility combines advanced manufacturing technologies with precision engineering to create professional-grade double courts that meet international standards. The factory utilizes automated production lines equipped with CNC machinery for precise cutting and welding of structural components, ensuring dimensional accuracy and structural integrity. The facility features dedicated zones for frame assembly, glass panel installation, and artificial turf integration, all operating under strict quality control protocols. Advanced surface treatment systems ensure superior rust protection and durability of metal components, while specialized testing equipment validates the structural stability and safety features of each court. The factory's climate-controlled environment maintains optimal conditions for materials processing and assembly, particularly crucial for the proper curing of adhesives and protective coatings. With a production capacity designed to meet growing market demands, the facility implements smart inventory management systems and just-in-time manufacturing principles to optimize efficiency. The factory also houses a research and development department focused on continuous product improvement and innovation in court design and materials.