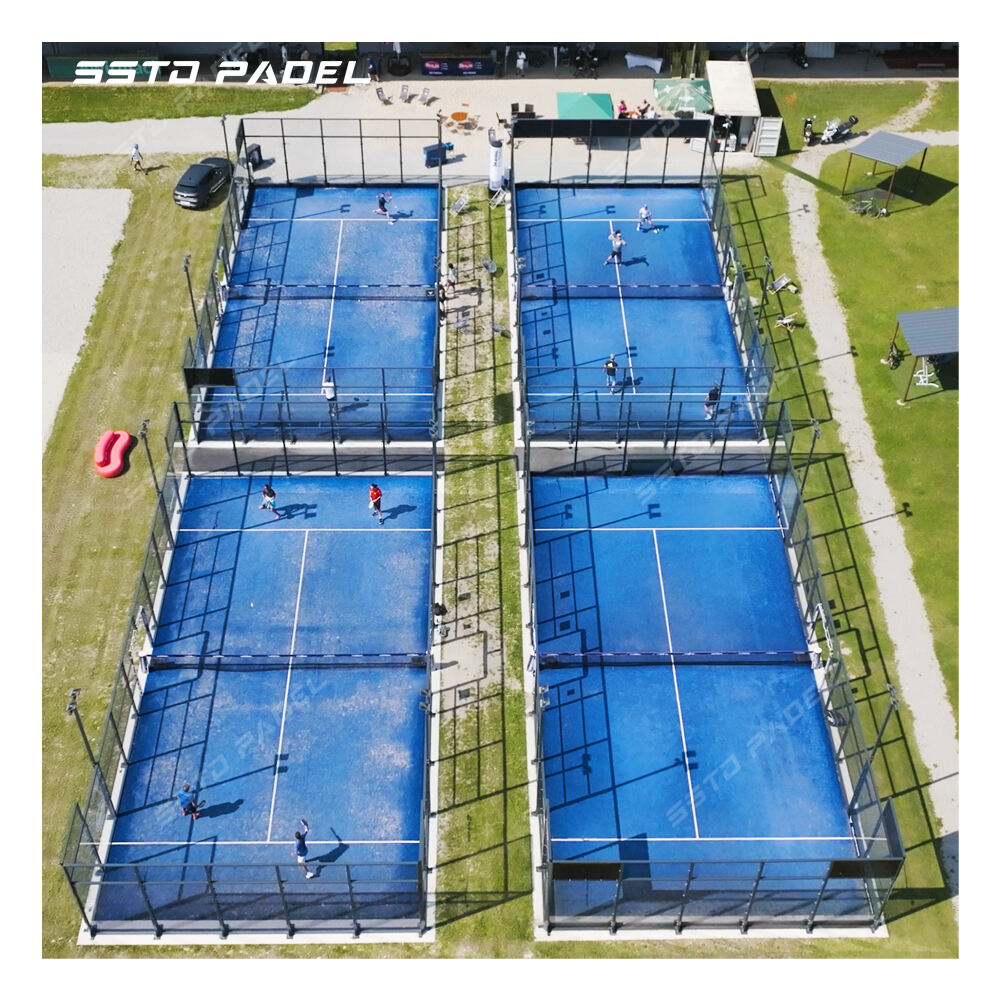

paddle tennis indoor factory

A paddle tennis indoor factory represents a state-of-the-art manufacturing facility dedicated to producing premium indoor paddle tennis courts and equipment. The facility encompasses advanced production lines equipped with precision machinery for crafting court surfaces, walls, and essential components. These factories utilize cutting-edge technology to ensure exact measurements and specifications, maintaining consistent quality across all products. The manufacturing process incorporates specialized materials designed specifically for indoor paddle tennis, including shock-absorbing flooring systems, transparent tempered glass panels, and professional-grade lighting installations. Quality control stations throughout the production line monitor every aspect of manufacturing, from initial material processing to final assembly. The factory's climate-controlled environment ensures optimal conditions for material handling and product construction, while automated systems manage inventory and track production efficiency. Modern CAD/CAM systems enable customized court designs to meet specific venue requirements, and dedicated research and development teams continuously work on improving court performance and durability. The facility also includes testing areas where finished courts undergo rigorous quality assessments to verify playability, safety, and compliance with international standards.